Industry efforts to improve the sustainability of air

travel

include everything from fuel-saving behavioral interventions for

pilots

and rethinking emissions-adding frequent-flyer

programs

to innovations around sustainable aviation

fuels

and carbon-labeled

travel.

But biomimicry, the

study of natural design — in this case, how animals move — has potentially the

most to teach us about optimizing the efficiency of aircraft themselves.

Image credit: Lufthansa

Group

Image credit: Lufthansa

Group

Earlier this month, the first Austrian

Airlines Boeing 777-200ER equipped with

AeroSHARK surface technology

successfully completed its maiden flight. On January 14, the “sharkskin”-coated

long-haul aircraft flew from Bangkok to Vienna — the first of four B777-200ERs

that Austrian Airlines plans to equip with the technology. The significantly

reduced frictional resistance from the film will reduce the Austrian Airlines

long-haul fleet’s CO2 emissions and fuel consumption; the modification of the

four aircraft will be completed by March 2025.

By applying a total of 830 square meters of sharkskin film per aircraft on the

surface of the fuselage and engine nacelles, a saving of approximately one

percent of the total fuel consumption per flight can be achieved. Applied to

four B777s, the technology can reach savings of about 2,650 tonnes of fuel and

over 8,300 tonnes of CO2 — the equivalent of roughly 46 flights from Vienna to

New York.

"Reducing our CO2 emissions in flight operations is at the center of our

sustainability efforts. The application of the ‘sharkskin’ developed by

Lufthansa Technik is an important

investment that will enable us to fly our long-haul aircraft more efficiently,”

said Austrian COO Francesco

Sciortino.

Jointly developed by Lufthansa Technik and BASF,

AeroSHARK coating consists of millions of transparent,

prism-shaped “riblets” approximately 50 micrometers in size. By mimicking the

properties of aerodynamic sharkskin, it optimizes aerodynamics in relevant areas

of aircraft. Applied to align with airflow, the riblets improve efficiency by

reducing friction; Lufthansa Technik says it can also improve lift if attached

to wings.

Austrian Airlines is the first airline to use this technology on the Boeing

777-200ER, but AeroSHARK has already taken to the skies around the world.

LATAM was the first airline outside the

Lufthansa Group and in the Americas region to adopt the technology. Since

December 2023, a modified aircraft has shown approximately a 1 percent reduction

in jet fuel consumption in daily operations. Based on the positive results,

LATAM plans to retrofit four more Boeing 777-300ER aircraft with AeroSHARK —

which is expected to save up to 2,000 metric tons of kerosene and 6,000 metric

tons of CO₂ emissions (equivalent to approximately 28 flights from São Paulo to

Miami on a Boeing 777) annually.

In August 2024, Taipei-based EVA

Air

became the first Asian airline to embrace the drag-reducing and hence

fuel-saving AeroSHARK technology — covering the fuselage and engine nacelles of

its entire cargo fleet of nine Boeing 777F long-range freighters modified with

the riblet film. EVA said the film has reduced frictional resistance so

significantly that fuel consumption and the resulting emissions are reduced by

around 1 percent — an annual savings of more than 2,500 metric tons of kerosene

and more than 7,800 metric tons of CO2 emissions.

A month later, All Nippon Airways (ANA) —

Japan’s largest airline — became the first individual airline worldwide to

operate both passenger and freighter variants of the Boeing 777 with AeroSHARK.

The first modified Boeing 777F began scheduled cargo flights in early September

2024, with plans to coat a 777-300ER passenger aircraft with AeroSHARK by spring

2025. Both aircraft will have nearly the entire fuselage covered with the

sharkskin-inspired film, resulting in estimated annual savings of approximately

250 metric tons of fuel and 800 metric tons of CO2 for each plane.

As of now, 17 Lufthansa Group aircraft modified with drag-reducing riblet film —

12 Boeing 777-300ERs of Swiss International Air Lines and four 777F of Lufthansa

Cargo — are roaming the skies. Along with Lufthansa’s Boeing 747-400 the squad

has already accumulated more than 100,000 flight hours with AeroSHARK.

Biomimicry in flight

Image credit:

Airbus

Image credit:

Airbus

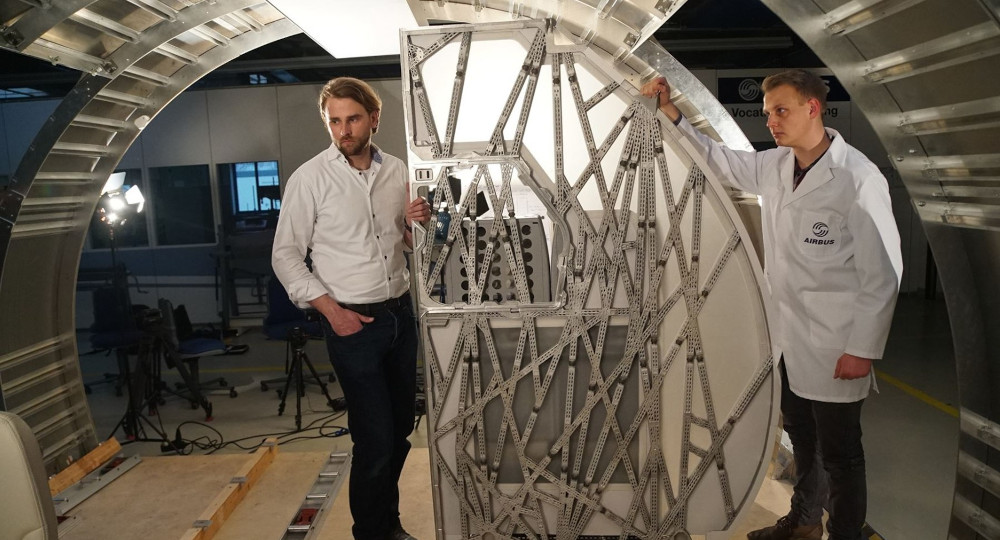

Airbus has been using biomimetic innovations to

improve the efficiency of its plane designs for over a decade. The early adopter

also drew inspiration from a shark when developing

“sharklets”

— vertical wing-tip extensions that resemble a shark’s dorsal fin — which was

added as a retrofit to its A320 Family aircraft in 2013. Mounted vertically

at the wingtips, these aerodynamic surfaces significantly reduce the size of the

wingtip vortex, thus reducing induced drag. Nature-inspired innovations also

helped Airbus develop lighter-weight galley

partitions

(now known as the Bionic

Partition)

designed to mimic properties of slime mold and bone

growth,

which allow planes to save a projected 465,000 metric tonnes of CO2 emissions

per year; and the company will install its eXtra Performance

Wings,

which mimic a bird’s feathers to provide multiple wing configurations that

dynamically adapt to flight conditions, for flight testing starting in 2025.

Get the latest insights, trends, and innovations to help position yourself at the forefront of sustainable business leadership—delivered straight to your inbox.

Sustainable Brands Staff

Published Jan 24, 2025 8am EST / 5am PST / 1pm GMT / 2pm CET