More and more automakers — including Bentley, Ferrari, Ford and Tesla, to name a few — have been developing circular, plant-based material innovations for use in their vehicles; and BMW and Volkswagen have joined the fun.

BMW’s circular seat design wins award

Image credit: Bcomp

Image credit: Bcomp

A collaboration between BMW M

— the performance-car subsidiary of BMW Group — and Swiss lightweighting

specialists Bcomp has been recognized by Altair’s

2024 Enlighten Awards, which highlight the

global automotive sector’s most innovative, sustainable developments. The

BMW M Visionary Materials

Seat, which rethinks the composition of car seats and is

manufactured with Bcomp’s ampliTex™

flax-based materials, won in the Sustainable Process category for its

lifecycle focus.

“We are already using existing technologies and materials to provide an outlook

on the possibilities for reducing emissions and conserving resources in the

future,” said Falco

Hollmann, Innovation

Manager Lightweight Construction & Sustainability at BMW M, when he

accepted the award. “This is not just about the substitution of materials, but

above all about the topic of design for circularity.”

The winning seat design re-envisions conventional manufacture and component

materials to introduce a lighter, circular product that meets the demands of

large-scale vehicle production. In addition to using natural and recycled

materials, less complex assemblies and monomaterials can be separated by type to

enable the recyclability of the seat at the end of its life. Bcomp says its

flax-fiber composites are CO2e-neutral from cradle to gate, can reduce

manufacturing-related emissions of high-performance composite parts by up to 85

percent compared to carbon fiber — depending on the application — and weigh up

to 50 percent less than current, large-scale automotive plastic parts.

Bcomp – founded as a garage project in 2011 with a mission to create lightweight

yet high-performance skis — has become a leader in high-performance, natural

fiber composites for the mobility-, recreational-, and mass transportation

sectors. The company also made a recent splash at NASCAR’s annual Chicago

Street Race, when the racing organization unveiled a prototype of an all-new

battery electric vehicle (BEV) with a body made from Bcomp’s flax

fiber

composite material. The plant-based material promises to reduce CO2 emissions of

traditional carbon fiber by up to 85 percent at similar stiffness, and improve

safety in motorsports thanks to a breaking behavior without sharp shattering — a

safety aspect that is especially relevant in bumper-to-bumper racing.

BMW first started to work with Bcomp’s materials in 2019 when it used

high-performance, natural-fiber composites in the BMW iFE.20 Formula E

car.

VW trialing hemp-based ‘leather’ for car interiors

Image credit: Volkswagen

Image credit: Volkswagen

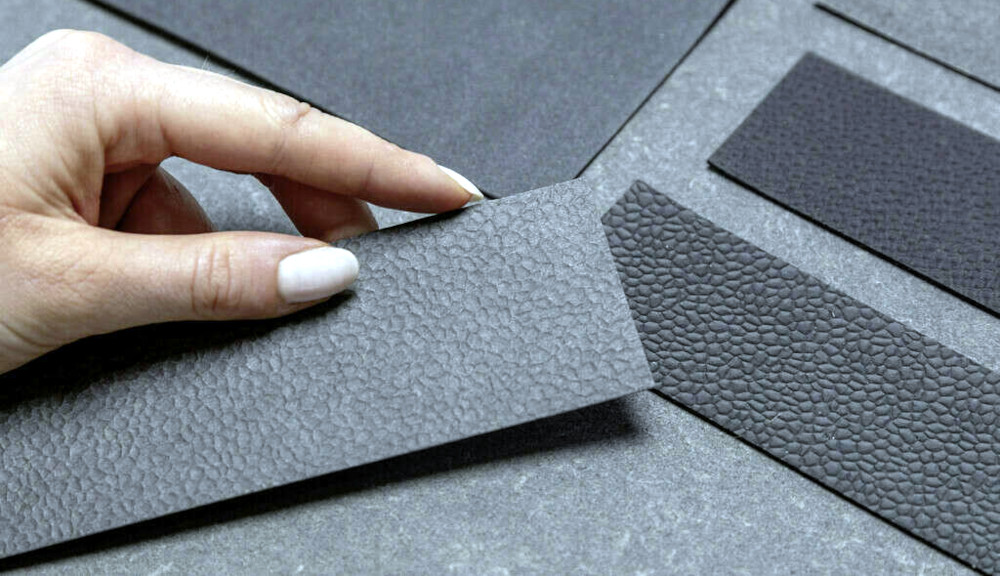

Meanwhile, Volkswagen has partnered with German startup

Revoltech to research and develop bio-based

materials based for use in automotive interiors.

The winning candidate, called LOVR™

(leather-free, oil-free, vegan, residue-based), is Revoltech’s first textile

solution. Made from residues from the regional hemp industry, LOVR is 100

percent plant-based, plastic free, fully recyclable and biodegradable, and can

be molded into a variety of textures and finishes — including, for Volkswagen’s

purposes, “leather.” The carmaker is testing LOVR for use as sustainable surface

material in Volkswagen models from 2028.

LOVR joins a growing variety of

plant-based

and

circular

leather alternatives that are offering product designers the same feel and

durability as their bovine counterpart, without the environmental

trade-offs

that can often come with conventional leather. Due to its versatility and ease

of processing, Revoltech says LOVR can be produced using existing industrial

processes — for easy scalability and integration into large-scale manufacturing

— and is a good candidate for use in industries including furniture, fashion and

automotive.

“The sustainable use of resources is a key pillar in our ACCELERATE strategy and

is therefore firmly anchored in our mindset and our actions. Our clear goal is

to fuse customer wishes, sustainability requirements and corporate interests,”

said Andreas

Walingen, Head of

Strategy at the Volkswagen brand, adding that the collaboration was a good

example of the benefits to be gained from the targeted combination of the

respective strengths of startups and established companies.

Volkswagen says the first presentations of LOVR have received a positive

response and feedback from customers.

Get the latest insights, trends, and innovations to help position yourself at the forefront of sustainable business leadership—delivered straight to your inbox.

Sustainable Brands Staff

Published Sep 6, 2024 8am EDT / 5am PDT / 1pm BST / 2pm CEST