The fashion world is renowned for creativity and innovation, with designers

fusing art with functionality. But behind its glamour lies the reality — it’s

one of the planet’s most polluting sectors. With 92 million

tons of textile

waste

generated annually and fashion accounting for 10 percent of global carbon

emissions,

traditional manufacturing processes are not just outdated — they’re destructive.

The prevalence of fossil fuel-based

fabrics,

combined with an intricate supply chain that stretches across continents, has

driven exploitation and chemical pollution throughout the industry.

More and more innovators are designing novel, plug-and-play solutions to help

rein in fashion’s many negative impacts — including biomimetic

technologies

that replace water- and chemical-intensive dyeing processes, creating circular

materials upcycled from everything from food

waste

to CO2

emissions,

and designing complex items such as shoes for easy disassembly and

recycling.

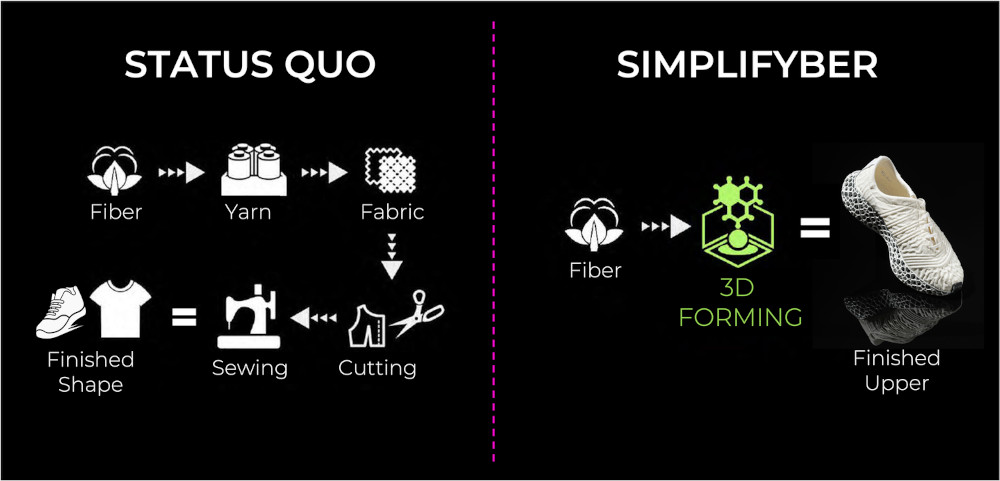

Adding to the list is Simplifyber, a North

Carolina-based startup that offers a whole new approach to textile

manufacturing. The company has created a cellulose-based liquid from renewable

plant sources that can be molded into a versatile textile, using its novel

technology. The company’s tech platform replaces 60 percent of the traditional,

resource-intensive processes related to garment production with a more

streamlined system that significantly reduces resource use and environmental

impact. The approach cuts down both waste and energy consumption, and offers a

scalable solution for sustainable fashion manufacturing.

"After 24 years in luxury fashion, working on runway collections in Europe

and the US, I saw firsthand how backward the manufacturing system is: an

inefficient bottleneck of spinning, weaving, cutting and sewing; coupled with

outsourcing to developing countries where there is a lack of oversight and

regulations — and consequently, pollution,” Simplifyber co-founder and CEO

Maria

Intscher-Owrang, who

previously worked as a designer at fashion houses including Alexander

McQueen and Vera Wang, tells Sustainable Brands® (SB). “I thought,

‘There has to be a better way.’”

From the kitchen to the lab

Image credit: Simplifyber

Image credit: Simplifyber

Simplifyber’s journey began with kitchen experiments by Intscher-Owrang and her

co-founder, Philip Cohen,

who were trying to find a more sustainable way to create fabrics.

“Maria and I were introduced by a mutual friend and classmate of mine from

business school,” Cohen tells SB. “After a couple of phone

calls, I asked Maria to come out to Nashville — where I was living at the

time — and show me what she had in mind. She asked if she could get a couple of

my kitchen pots and pans dirty; and within a few minutes, she was smearing this

fiber paste she had made in my kitchen onto a plastic mannequin that she had

brought with her. After the paste dried, we peeled it off the mannequin and it

was a vest.

“I could see the vision and a clear path forward; and the proposition to disrupt

and improve a massive industry like fashion was exciting to me. And maybe the

most exciting thing was that this idea could be applied to various markets

outside of fashion, as well.”

The two tested different fibers, looking for a method to mold them directly into

shape without the traditional weaving and sewing steps.

“We were just trying to see what fibers would be like when worked directly into

a form," Intscher-Owrang recalls.

However, they quickly realized that the complexity of their idea required

professional tools and expertise beyond what they could do at home. So, in 2021,

they assembled a team of chemists and partnered with research groups to refine

their early concept of molding fibers directly into garments. This transition

marked a turning point for the company — moving it from small-scale experiments

to a sophisticated lab environment. The result: pouring liquid cellulose,

derived from renewable plant sources, into molds — eliminating the need for

spinning, weaving, cutting and sewing.

“Much like traditional manufacturing, we start with fiber — but then, skip all

the other steps and jump straight to the end by pouring our liquid slurry of

fibers into a three-dimensional mold. These fibers are chemically bonded

together to create our products,” Intscher-Owrang explains. “So, at scale, this

is vastly more efficient and automated and will enable a relatively small

facility to make in a single day what a traditional sewing factory makes in a

month with 100 sewers.”

Simplifyber hasn’t just introduced new materials — it has reimagined the entire

textile manufacturing process. By eliminating 60 percent of traditional

manufacturing steps, the process dramatically reduces waste, energy use and the

greenhouse gas emissions generated by conventional methods.

The company is currently focusing on applications in the automotive and

especially footwear industries. Its technology can produce shoe uppers in a

matter of hours — a fraction of the time needed for conventional methods.

Simplifyber textiles are made from biodegradable, bio-based materials sourced

from a variety of plant-based and recycled sources — including cellulose derived

from FSC-certified wood pulp, recycled cardboard, hemp and even recycled

clothing — ensuring a lower resource demand compared to traditional fabrics.

Another advantage of Simplifyber’s process is the potential for on-site

production. With this technology, apparel companies and manufacturers can

produce garments at their own facilities — reducing the need for international

transportation.

Enhancing garment worker value

Image credit: Simplifyber

Image credit: Simplifyber

As industries adapt with automation, concerns about job displacement arise —

especially in fashion, where many garment workers are sourced from

developing countries. However, Intscher-Owrang believes that Simplifyber’s

approach can enhance the value of skilled garment workers rather than displace

them. She explained that Simplifyber is not trying to replace people, but

instead trying to eliminate the most repetitive and labor-intensive parts of the

process so that workers can focus on what really matters: their craftsmanship.

“Traditional manufacturing is not going to go away, because there are a lot of

products that you can’t make this way [molding]; but it can replace a layer of

what can be replaced and raise the perception and value of things that can’t,”

she says.

Through automation, Intscher-Owrang believes that those whose skills are truly

irreplaceable can be fairly compensated, positioning them as vital players in a

more efficient and equitable fashion industry.

And as most clothing and shoe brands hire out their manufacturing, Simplifyber

would just be a different supplier. This adaptability allows its technology to

integrate seamlessly into existing supply chains, encouraging brands to rethink

their production processes.

Future collaborations and commercialization

As Simplifyber prepares to launch its first product — a shoe upper — next year,

the reaction from the fashion world has been overwhelmingly positive; excitement

is building among brands eager to integrate this technology into their

operations.

“For now, we’re focused on manufacturing ourselves because we can’t just

introduce a new piece of equipment and expect people to know how to use it,” she

explains. “We need to demonstrate what’s possible with real products, create

tangible examples, and collaborate closely with factories and brands. This way,

we can help manufacturers feel comfortable with the new technology.”

Intscher-Owrang’s extensive network in the fashion industry has been

instrumental in helping Simplifyber collaborate with prominent brands: The

company recently unveiled the first look at its first collaboration — the

GANNI x Simplifyber "Moon

Shoe,"

produced with Scandinavian ready-to-wear brand

GANNI — set to debut at Paris Fashion Week

Spring 2025. Another collab with a car manufacturer that will be announced

soon.

In the coming years, Simplifyber aims to further enhance its impact by scaling

production and expanding its offerings beyond footwear and automotive parts.

“In five to ten years, our goal is to diffuse this technology by selling both

the equipment and the material slurry. This approach will enable us to reach

more of the industry than we could as just a manufacturer,” Intscher-Owrang

explains. “It’s crucial for us to transform as much of the industry as possible

and open up opportunities for others to adopt this innovative manufacturing

process.”

Get the latest insights, trends, and innovations to help position yourself at the forefront of sustainable business leadership—delivered straight to your inbox.

Scarlett Buckley is a London-based freelance sustainability writer with an MSc in Creative Arts & Mental Health.

Published Dec 4, 2024 8am EST / 5am PST / 1pm GMT / 2pm CET