Researchers at ETH Zurich — a public research university

in Zürich, Switzerland — have developed a type of chocolate that makes

use of an agricultural waste stream and is more sustainable and nutritious than

conventional varieties. The team has also joined forces with the chocolate

industry to investigate the potential for making maximum use of the cocoa fruit,

which would increase the profitability of cocoa cultivation while making

chocolate a healthier indulgence.

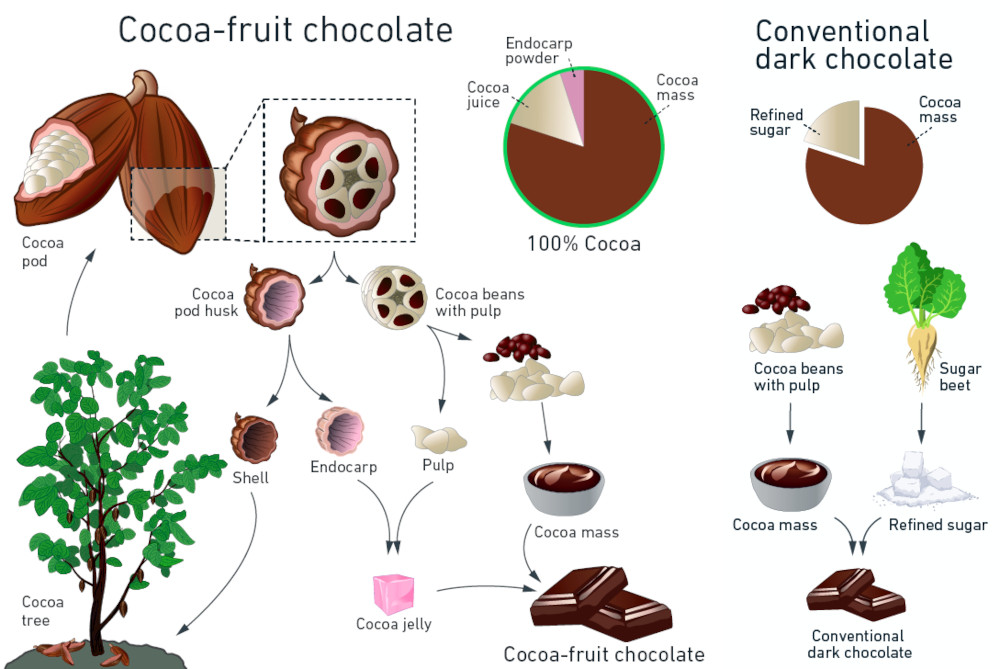

The main components of conventionally produced chocolate are cocoa mass

(beans) and cocoa butter, which are extracted from the cacao fruit.

But cacao fruit is a

superfood

that contains additional, valuable ingredients that have been largely

underutilized until now — in producing conventional chocolate, the industry

wastes 70 percent of the cacao

pod. And

while brands such as Barry

Callebaut

and Blue Stripes are exploring the many

potential uses for the rest of the fruit, efforts to make use of these

nutritious waste products have yet to scale.

So, as part of an Innosuisse

project, a research team led by emeritus ETH professor Erich

Windhab, worked together

with Koa — a Swiss-Ghanaian startup

that upcycles cacao fruit, especially the typically discarded pulp, into

value-added ingredients to improve the resilience of cocoa farms and reduce the

carbon footprint of the West African cocoa industry — and Swiss chocolate

manufacturer Felchlin to develop their own recipe

for cocoa-fruit chocolate.

Image credit: ETH Zurich

Image credit: ETH Zurich

The ETH researchers used the flesh and parts of the cacao fruit shell (called

the endocarp) for their cocoa-fruit chocolate recipe — processing it into

powder and mixing it with part of the pulp to form cocoa gel. The resulting

sweet, gel substance can replace the added powdered sugar that is normally part

of the chocolate recipe.

However, landing on the perfect cocoa-fruit chocolate recipe was a challenge:

Too much fruit juice extracted from the pulp made for a clumpy chocolate (an

issue usually solved by adding powdered sugar), but too little resulted in an

insufficiently sweet product. In the end, the experiments showed that chocolate

may contain up to 20 percent gel, which equivalates to the sweetness of

chocolate with 5 to 10 percent powdered sugar — in comparison, conventional dark

chocolate can easily contain between 30 and 40 percent powdered sugar.

Healthier, more sustainable and more lucrative for farmers

According to Kim Mishra —

former postdoc researcher at ETH and main author of the Nature

Food study on the project — ETH’s

cocoa-fruit chocolate was then vetted by a panel of taste-testers from the Bern

University of Applied Sciences, with some containing

various amounts of powdered sugar and others containing the new variety

sweetened with cocoa gel: “This allowed us to empirically determine the

sweetness of our recipe as expressed in the equivalent amount of powdered

sugar,” he explains.

In addition to meeting expectations for flavor, by using cocoa gel as a

sweetener, cocoa-fruit chocolate boasts about 20 percent higher fiber content

than your average European dark chocolate (15 grams versus 12 grams per 100

grams) — which prevents blood sugar levels from rising too rapidly when

consuming chocolate — and only 23 grams of saturated fat, as opposed to the

usual 33 grams (a reduction of 30 percent).

Planting seeds for added value

The biggest opportunities here could be for smallholder cocoa

farmers

— the majority of whom struggle to earn a living

income

from their work. By scaling demand and processing capacity for more parts of the

cacao pod, farmers can eliminate waste, diversify their product

offerings

and increase their income. And if most of the fruit can be used to produce

cocoa-fruit chocolate, only the shell remains — which is traditionally used as

fuel or composting

material.

“This means that farmers can not only sell the beans, but also dry out the juice

from the pulp and the endocarp, grind it into powder and sell that, as well,”

Mishra says. “This would allow them to generate income from three value-creation

streams. And more value creation for the cocoa fruit makes it more sustainable.”

And while this could be a win on many fronts, ETH’s cocoa-fruit chocolate won’t

be hitting store shelves anytime soon.

“Although we've shown that our chocolate is attractive and has a comparable

sensory experience to normal chocolate, the entire value-creation chain will

need to be adapted — starting with the cocoa farmers, who will require drying

facilities,” Mishra says. “Cocoa-fruit chocolate can only be produced and sold

on a large scale by chocolate producers once enough powder is produced by

food-processing companies.”

The first step has been taken: ETH has filed a patent for its cocoa-fruit

chocolate recipe. The development of cocoa-fruit chocolate is a promising

example of how technology, nutrition, sustainability and income diversification

for small farmers can work in tandem to improve the entire value-creation chain

of one of our most popular commodities.

Get the latest insights, trends, and innovations to help position yourself at the forefront of sustainable business leadership—delivered straight to your inbox.

Sustainable Brands Staff

Published Jun 18, 2024 8am EDT / 5am PDT / 1pm BST / 2pm CEST