As we well know,

plastic has become one of the world’s most prolific polluters. According to

the OECD, 22 million

tonnes

of plastic waste leaked into the environment in 2019 — a number projected to

double by 2060 — and roughly 20 million metric

tons of that ends up in the world’s

waterways every year.

New strategies for tackling the issue continue to emerge from innovators

large

and

small;

and until an enforceable plastics

treaty

is in place and brands and plastic producers turn their commitments into action,

academic researchers continue to concoct potential solutions.

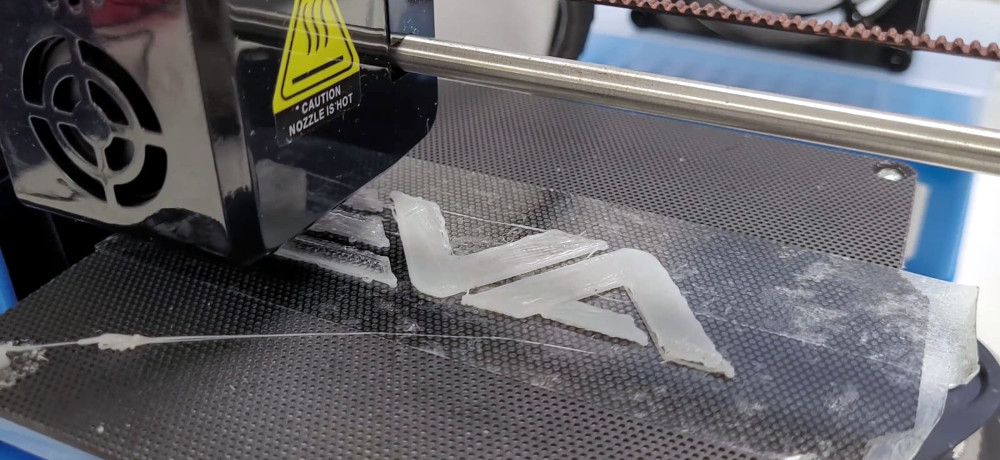

Scottish startup creates ‘smart’ plastic that self-destructs in water

Image credit: E.V.A Biosystems

Image credit: E.V.A Biosystems

University of Edinburgh startup E.V.A

Biosystems has developed a plastic that can sense

when it’s in the ocean and break itself down without creating microplastics.

E.V.A’s solution adds special bacteria to conventional plastic that can detect

when they’re in aquatic environments and activate enzymes that break down the

material. And unlike when plastics slowly degrade in landfills or aquatic

environments, or even during most recycling

processes,

E.V.A said the process does not create harmful

microplastics.

“We’re all struggling with plastic pollution; and while there are many people

developing biodegradable

plastics,

they’re too expensive and only make up about 1 percent of the world’s plastic,”

said E.V.A founder Dr Alexander

Speakman, who received

his PhD in Bioengineering at the University of Edinburgh. “Our technology works

with existing plastics, making them ‘smart’ enough to break down when they end

up where they shouldn’t be, like in our oceans or landfills.”

The new solution won top prize in the Net Zero category at this year’s

Converge

Awards

— which highlight new Scottish academic innovations each year. E.V.A. earned a

£30,000 cash prize, as well as £19,500 of in-kind business-development support

from Scottish energy company SSE (which sponsored the award) and Converge’s

network of industry partners. The company also took home the £20,000 IBioIC

Award — presented to a biotech business with a product or process that

addresses a real market need.

Rice researchers develop sticky, biomimetic solution to marine plastic pollution

Image credit: Georg

Eiermann

Image credit: Georg

Eiermann

Meanwhile, in the US, scientists at Texas’ Rice

University have been inspired by nature’s adhesive

genius — in this case, the sticky power of mussels — to create bioengineered

microorganisms with powerful cling capability that could transform environmental

cleanup. By combining this amplified adhesive power with an enzyme that breaks

down harmful plastics, their discovery offers a potential new tool for tackling

plastic pollution — especially, in marine environments.

According to the research, published in the journal, Small

Methods, the

innovation could also curb biofouling — the accumulation of microorganisms,

plants, algae and small animals on submerged surfaces that can damage ships’

hulls, underwater structures and pipes — addressing long-standing challenges in

industries ranging from shipping to medicine.

PET, a popular plastic for packaging that makes up the majority of global

plastic

pollution,

is notoriously resistant to degradation — taking centuries to decompose. The

Rice team’s innovation allowed it to create adhesive bacteria and proteins that

could help countries worldwide more efficiently decompose PET.

“Very excitingly, our research holds promise for addressing the growing problem

of plastic pollution in the US and across the globe,” said study leader Han

Xiao — director of Rice’s

Synthesis X Center; an associate professor of

chemistry, biosciences and bioengineering; and a Cancer Prevention and

Research Institute of Texas (CPRIT) scholar.

Tackling plastic pollution

The engineered bacteria were designed using genetic code expansion technology —

incorporating a natural amino acid called 3,4-dihydroxyphenylalanine

(DOPA), responsible for mussels’ adhesive properties — which significantly

enhanced their ability to bind to PET surfaces.

The altered bacteria, tested on PET samples at 37°C, demonstrated a 400-fold

increase in adhesion. The bacteria was then united with an enzyme called

polyethylene terephthalate hydrolase to break the material into smaller, more

manageable fragments — resulting in what the researchers call a significant

amount of degradation of the plastics overnight.

This approach could provide a novel solution to plastic recycling,

offering a faster and more efficient way to reduce plastic waste and its

environmental impact.

“Our approach underscores the innovative utility of genetic code expansion in

material and cellular engineering,” Xiao said. “It can potentially transform

bioengineering applications and solve real-world problems.”

Other applications

In addition to addressing plastic pollution, the DOPA-modified proteins showed

strong bonding capabilities to organic and metallic surfaces — creating a

barrier that prevents the accumulation of microorganisms and other materials, which could be a game-changer in fighting biofouling.

The researchers’ discovery has even broader applications, including in the

healthcare field. For example, it can be used to prevent bacterial growth on

medical devices, making them safer and more effective.

“This will open up new avenues for leveraging these interactions to develop

smart material-protein conjugates for various biomedical applications like

implantable medical devices, tissue engineering and drug delivery,” said Mengxi

Zhang, first author of the study and a graduate student in chemistry.

Adhesion in wet environments is an ongoing business challenge, and the Rice team

isn’t the first to be inspired by mussels for potential solutions: A startup

called Mussel Polymers — one of 10 winners of

the Biomimicry Institute’s 2021 Ray of Hope

Prize

— developed a high-performance, non-toxic adhesive modeled on the proteins

mussels use to adhere to surfaces in extreme marine environments, that is 300

percent stronger than other underwater adhesives. Mussel Polymers can also be

used in a number of industries, but it was brought to market first for dental

and biomedical applications and coral restoration.

Get the latest insights, trends, and innovations to help position yourself at the forefront of sustainable business leadership—delivered straight to your inbox.

Sustainable Brands Staff

Published Oct 9, 2024 2pm EDT / 11am PDT / 7pm BST / 8pm CEST