Concrete and cement remain foundational to global infrastructure, but their

environmental toll is undeniable. Accounting for roughly 8% of global carbon

emissions,

cement’s footprint is larger than that of aviation or shipping. Yet recent

developments suggest we may be on the cusp of a breakthrough in sustainable

construction: Around the world, more than 60

companies

are now developing low-carbon concrete

solutions

and emerging research is yielding breakthroughs — driven by regulation,

procurement initiatives and growing market demand.

In this Innovation

Watch, we dive

into five of the most compelling ‘green’ concrete technologies — illustrating

that the future of construction can be not just low-carbon but smart, circular

and resilient.

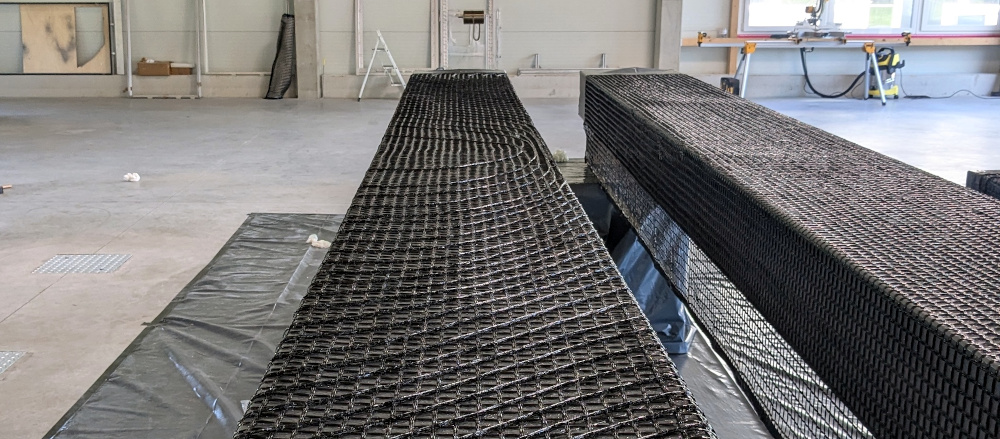

3D-printed basalt reinforcement

Image credit: Fiber Elements

Image credit: Fiber Elements

Steel-reinforced concrete is one of the most widely used construction

materials on the planet, and also one of the most carbon-intensive. Steel

contributes significantly to the embodied

carbon

of buildings and infrastructure while also adding weight, increasing corrosion

risk and inflating costs. Austrian startup Fiber

Elements is looking to shift that paradigm with a

lighter, stronger, more sustainable alternative: 3D-printed basalt fiber

grids that can fully replace steel reinforcement in concrete structures.

How it works

The company’s system uses mineral-based basalt fibers — derived from volcanic

rock — to create structural grids that outperform steel in strength and

durability, while weighing around two-thirds less. These grids are formed using

automated, precision-manufacturing methods that Fiber Elements has developed in

collaboration with leading Austrian research institutions. The result is not

just a drop-in replacement for steel, but a redesigned approach to reinforcement

— optimized through advanced structural analysis. The material doesn’t corrode,

performs well in extreme environments, and can be fully recycled at end of life.

According to the company, switching from steel to basalt reinforcement can

reduce emissions by up to 70%.

What makes the technology particularly scalable is its modular, decentralized

model. Fiber Elements plans to roll out compact nano-factories that can be

placed directly on construction sites, producing reinforcement components where

they’re needed and slashing the emissions and costs tied to transport. This

makes it well-suited for large infrastructure projects, tunnels, bridges and

modular buildings that benefit from just-in-time prefabrication.

Why climate-conscious builders should care

Basalt reinforcement addresses several pain points in the construction sector:

embodied carbon, logistics, labor intensity and material degradation. At a time

when regulations are tightening around the environmental performance of

buildings and infrastructure, Fiber Elements’ approach offers a credible,

high-performance alternative to a deeply entrenched material. With €2.6

million in new funding and early

deployments already underway, the company is gearing up to scale and could play

a key role in mainstreaming low-carbon construction solutions.

Waste-based concrete could extend the life of sewer systems

Image credit:

Freepik

Image credit:

Freepik

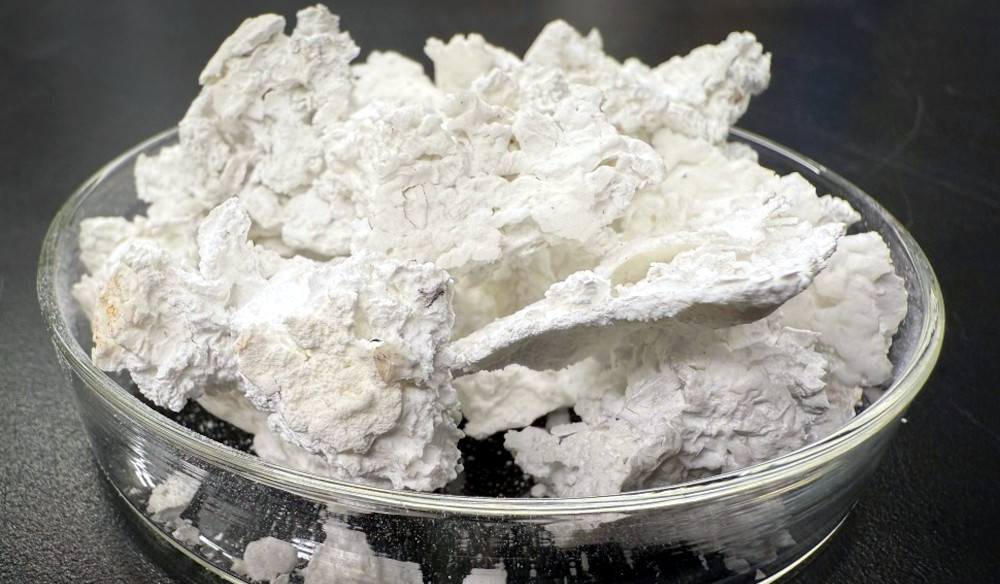

Maintaining underground infrastructure is one of the most overlooked, and

costly, challenges in modern construction. Researchers at the University of

South Australia (UniSA) have developed a new type of

concrete

designed to tackle this problem — using industrial waste materials to create a

stronger, more durable alternative. By reusing alum-based water treatment sludge

— typically a landfill-bound byproduct — the team has developed a material that

performs significantly better than conventional cement in key stress and

corrosion metrics.

How it works

The innovation combines two main ingredients: blast-furnace slag — a common

cement substitute — and sludge from water treatment plants. The resulting

alkali-activated material (AAM) forms a concrete mix that boasts more

than 50% higher compressive strength than standard cement-based alternatives.

More importantly, it shows improved resistance to both acid exposure and

microbial attack — two of the biggest threats to sewer infrastructure.

Sulfur-oxidizing bacteria, which are known to degrade concrete from within, are

less effective against this waste-based mix — potentially extending the service

life of pipes and reducing the frequency of costly repairs.

Because the sludge used is a waste product, the solution supports circular

construction practices by diverting material from landfill and reducing the need

for virgin cement. It also cuts emissions associated with both transport and

material production. The project, led by Professor Yan

Zhuge and developed in

collaboration with SA Water Corporation, is part

of a broader push to explore how AAMs could improve the sustainability and

performance of critical infrastructure.

Why climate-conscious engineers should care

This innovation offers a double win: It repurposes waste and delivers stronger,

longer-lasting infrastructure with a lower environmental footprint. For cities

and utilities facing growing pressure to upgrade aging sewer systems without

increasing emissions, UniSA’s research offers a practical, scalable solution. As

the material continues to be tested and refined, it could revolutionize how we

build and maintain essential infrastructure below ground.

AI enables smarter concrete use

Image credit:

Converge

Image credit:

Converge

While much attention has been given to developing lower-carbon concrete

alternatives, less has been done to address how concrete is used in practice.

UK-based startup Converge is targeting that gap

with a data-driven platform designed to improve how concrete is mixed, poured

and managed on site — reducing both waste and emissions without altering the

material itself.

How it works

At the core of Converge’s platform is

ConcreteDNA — a

system that uses embedded sensors to track key data points including

temperature, humidity and strength development during concrete pours. These

real-time insights are then fed into predictive AI models that simulate how the

concrete will behave as it cures. The platform gives engineers a clearer picture

of material performance — allowing them to adjust mix compositions, curing

schedules and logistics to reduce delays, avoid over-engineering and cut

emissions.

The system effectively replaces guesswork with data, making it possible to

optimize concrete use without compromising safety or performance. By eliminating

unnecessary overuse of cement (a common practice driven by caution) ConcreteDNA

helps reduce embodied carbon across a project. And because it operates within

existing construction workflows, it offers immediate benefits without requiring

new materials, equipment or training.

Why climate-conscious builders should care

As the construction industry looks for practical ways to reduce its carbon

footprint, tools that improve how materials are used can be just as impactful as

the materials themselves. Converge’s digital intelligence can make traditional

concrete smarter — enabling lower emissions, faster builds and fewer errors

without disrupting current practices. With €19.4

million

in fresh funding and plans to expand globally, the company is well positioned to

bring these efficiencies to scale. For contractors and developers under pressure

to decarbonize, platforms such as ConcreteDNA could help shift the conversation

from what concrete is to how smarter use can deliver better outcomes across the

board.

Concrete that can heal its own cracks

Image credit:

Freepik

Image credit:

Freepik

Concrete may be strong, but it isn’t infallible. Over time, it cracks — from

traffic loads, freeze-thaw cycles, drying shrinkage or structural stress — and

even microscopic cracks can lead to major failures. Water and air can penetrate

the surface, corroding the steel reinforcement inside and weakening buildings,

bridges, and roads.

Now, researchers at Texas A&M University are exploring a nature-inspired

approach

that could help concrete repair itself — with no human intervention required.

Their goal is to develop a biomimetic, self-healing concrete that protects

infrastructure, reduces maintenance emissions and prevents failures that can

cost money and lives.

How it works

The research team, led by Dr. Congrui Grace

Jin, took

inspiration from lichen — the symbiotic organism made of fungi and algae

that survives in some of the harshest conditions on Earth. They developed a

synthetic system that mimics this partnership, pairing cyanobacteria with

filamentous fungi. In this engineered relationship, the cyanobacteria provide

nutrients while the fungi produce minerals that naturally fill in and seal

cracks. Unlike existing self-healing concrete

solutions, which often

rely on microcapsules or bacteria that require a continuous external nutrient

supply, this approach is designed to operate independently. The microbial pair

can survive using only sunlight, air and water — making it potentially viable in

a wide range of real-world environments.

In lab tests, the system was able to produce minerals inside cracked concrete

and begin the healing process under standard environmental conditions. The

researchers are now working to further test the durability and scalability of

the solution, and to understand how public perception might influence the

adoption of living systems in construction materials.

Why climate-conscious engineers should care

Self-healing concrete has long been viewed as a promising frontier for

resilient, low-maintenance infrastructure; but many existing systems fall short

on autonomy or scalability. By drawing from biological systems rather than

synthetic additives, this new approach could pave the way for more durable

infrastructure with fewer emissions from repairs and replacements. As cities and

countries grapple with the rising costs of aging buildings and streets,

materials that extend the life of concrete without intensive intervention could

play a key role in building safer, more sustainable infrastructure. If further

research confirms its potential, this lichen-inspired system may offer a rare

win-win: lower maintenance costs and longer-lasting structures with a biological

assist.

Using the ocean to decarbonize concrete

Image credit: Northwestern

University

Image credit: Northwestern

University

While carbon capture and

storage

typically focuses on burying CO₂ underground, researchers at Northwestern

University are exploring a more integrated, materials-based

solution.

Their approach uses seawater, carbon dioxide and clean electricity to produce

minerals that can replace key ingredients in concrete while permanently storing

carbon in the process.

How it works

The process is inspired by marine organisms such as corals and shellfish, which

naturally form mineral structures that trap carbon. Instead of relying on

biology, the Northwestern team uses electrochemistry: Electrodes submerged in

seawater generate hydroxide ions and hydrogen gas by splitting water. When CO₂

is bubbled into this solution, it reacts with calcium and magnesium ions

naturally found in seawater to form solid minerals such as calcium carbonate and

magnesium hydroxide. These minerals are then harvested and used as substitutes

for sand and other materials in concrete, cement, plaster and even paints.

The resulting material can hold more than half its weight in CO₂ without

compromising structural integrity. Its properties — including shape, density and

porosity — can also be tuned depending on the application. The process

additionally produces hydrogen as a clean fuel by-product, adding another layer

of climate value. While the technology is currently operating at lab scale, the

team is working with construction giant Cemex to explore pathways to

industrialization.

Why climate-conscious builders should care

This innovation offers a dual benefit — removing CO₂ from the atmosphere and

embedding it into long-lived construction materials. By using treated seawater

and modular land-based reactors, the system avoids disruption to marine

ecosystems while remaining scalable near industrial sites. The potential to

create a decentralized, plug-and-play solution for carbon capture — one that

turns emissions into building inputs — could be transformative. If successfully

scaled, it would allow the construction industry to shift from being a major

emitter to an active participant in carbon sequestration — using the ocean not

as a dumping ground, but as a resource for building a more climate-resilient

future.

Get the latest insights, trends, and innovations to help position yourself at the forefront of sustainable business leadership—delivered straight to your inbox.

Tom is founder of storytelling strategy firm Narrative Matters — which helps organizations develop content that truly engages audiences around issues of global social, environmental and economic importance. He also provides strategic editorial insight and support to help organisations – from large corporates, to NGOs – build content strategies that focus on editorial that is accessible, shareable, intelligent and conversation-driving.

Published Sep 22, 2025 8am EDT / 5am PDT / 1pm BST / 2pm CEST