Automakers including

BMW,

Ford,

Renault

and

Volkswagen

are among those already seizing economic and operational benefits by expanding

circular manufacturing processes and supply chain partnerships. Now, in a time

of ever-growing economic and geopolitical

instability,

three of their peers are increasing operational resilience by driving the

movement forward.

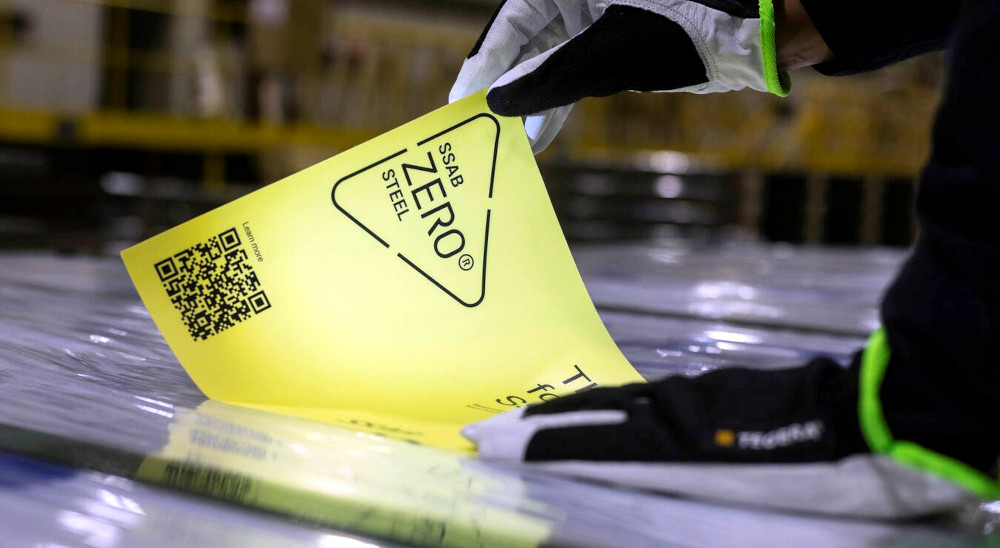

Volvo cutting CO₂ emissions with recycled steel partnership

Image credit: Volvo

Cars

Image credit: Volvo

Cars

Volvo Cars has signed a new agreement with Swedish

steel firm SSAB for the supply of high-quality,

recycled and near zero-emissions steel starting from 2025. Volvo is the first

car maker to partner with SSAB for recycled, near-zero-emission steel for serial

production deliveries.

One of our most used materials, the steel industry produces over 1.8 billion

metric

tons

annually. Sadly, it is also a massive polluter: Traditional steelmaking

processes

rely heavily on carbon-intensive equipment such as blast furnaces, emitting

around 1.8 tons of CO2 for every ton of steel

produced

— roughly 11

percent

of the world's total greenhouse gas output.

“One of the biggest sources of CO₂ emissions in our production process is the

steel we use to build our cars, averaging 25 percent of all material-related

emissions for a new Volvo car,”

says

Chief Supply Chain and Manufacturing Officer

Francesca Gamboni. “We

work towards achieving net-zero greenhouse gas emissions by 2040, and cutting

steel-related emissions really has the potential to move the needle.”

The recycled steel — which meets the same safety-related requirements as primary

steel in terms of strength and durability — will be used in components of

Volvo’s forthcoming, fully electric EX60 SUV, as well as other cars based on

its next-generation SPA3 car

architecture.

SSAB’s closed-loop system recycles scrap steel, significantly reducing CO₂

emissions and keeping materials and natural resources in use for longer.

Compared with traditionally produced steel in Europe, SSAB’s recycled steel

generates almost 100 percent less CO₂ emissions in own operations and is made

with a recycled content of almost 100 percent.

In addition to buying recycled and near-zero-emission steel, Volvo Cars will

also sell its scrap steel to SSAB to be recycled at the company’s mill in

Oxelösund into decarbonized steel. The agreement is an extension of a

long-term collaboration between the two companies, with the goal of leading an

industrywide transition to decarbonized steel.

“This agreement marks a significant milestone on our journey toward steelmaking

with virtually no fossil CO₂ emissions,”

says Asma

Manesh, Commodity Manager

Scrap at SSAB. “The conversion of our Oxelösund site will not only enhance our

production competitiveness but also enable us to cut emissions equivalent to 3

percent of Sweden’s total CO₂ output — and high-quality steel scrap is an

important factor in this equation.”

Volvo Cars is committed to achieving net-zero emissions by 2040. By 2030, the

aim is to have reduced CO₂ emissions per car by 65-75 percent compared to a 2018

baseline. The SSAB partnership supports this, as well as Volvo Cars’ circularity

ambitions — which include achieving an average of 30 percent recycled content

across the fleet by 2030, and for new car models released from 2030 to contain

at least 35 percent recycled or bio-based content.

Mercedes, Modern Meadow partner to scale bio-based, circular leather alternative

Image credit: Mercedes-Benz

Image credit: Mercedes-Benz

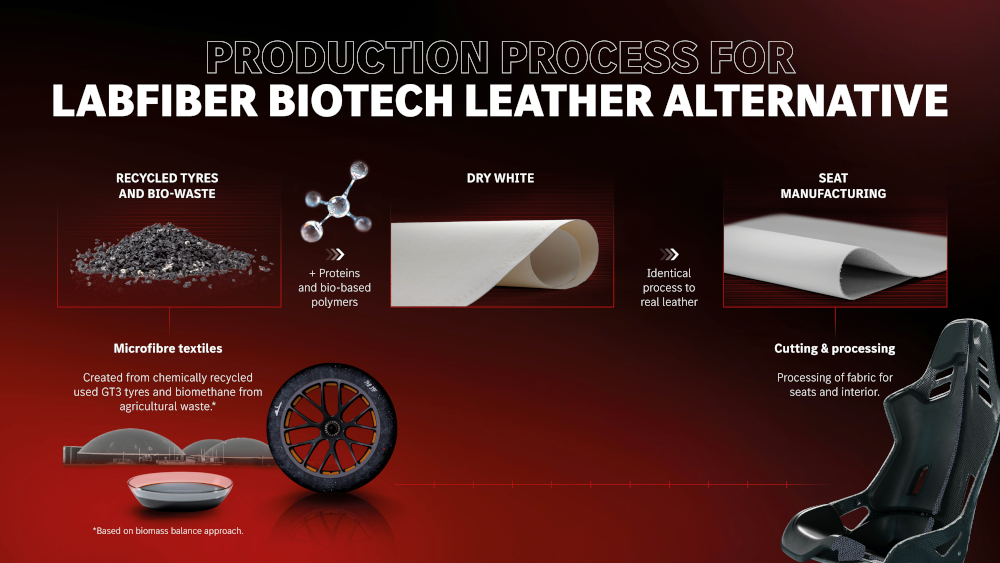

Meanwhile, Mercedes-Benz has teamed up

with materials-science company Modern

Meadow

to develop a bio-based leather alternative for its Concept AMG GT

XX

technology program. The aim of the development partnership is to further develop

Modern Meadow's INNOVERA™ (fka

Bio-VERA™)

— a high-performance, upcycled alternative to traditional leather — for series

production and set new standards in vehicle interiors.

INNOVERA is made from a combination of plant-based proteins, biopolymers and

post-consumer waste to replicate the look and feel of conventional, bovine

leather. For the Mercedes-Benz partnership, the post-consumer waste component

will come from chemically recycled tires from Mercedes' AMG

GT3 race cars.

"At Modern Meadow, we are redefining automotive interior possibilities with

INNOVERA — our next-generation transformative material that brings beauty,

performance and sustainability into perfect balance," said CEO David

Williamson, PhD. "In

our development partnership with Mercedes-Benz, we have used INNOVERA to create

a new luxury leather alternative without sacrificing aesthetics, versatility and

texture. It looks and feels as good as it performs."

Modern Meadow's INNOVERA achieves more than 80 percent renewable carbon content

and is completely animal-free. INNOVERA requires no special preservation or

storage conditions, which reduces complexity and costs, and is adaptable to any

standard manufacturing process.

In the Concept AMG GT XX, one scrap tire provides the basis for approximately

four square meters of the custom INNOVERA material — which will be used as

covering for the black seat pads of the car’s bucket seats. Modern Meadow says its bio-based nature

makes it breathable, waterproof and lighter than traditional materials; and its maximum tensile strength is twice as high as that of

traditional materials.

JLR driving over £100m in value from industrial reuse initiatives

Image credit:

JLR

Image credit:

JLR

And Jaguar Land Rover recently

revealed

how it is reducing waste across its industrial operations in the UK and Europe

through a £100m reuse, refurbishment, repurposing and recycling drive.

As its electrification transformation continues with the upcoming launch of

Range Rover Electric,

JLR’s industrial operations are readying themselves for the next generation of

electric vehicles and undergoing a revamp across all facilities.

As a result, tens of thousands of pieces of equipment and tools — spanning from

entire production lines to screwdrivers — have been put back in circulation,

when possible, after considering factors such as standard compliance,

availability of spare parts, cost of refurbishment and servicing, potential

scrap as well as sale revenues.

Instead of buying new, JLR has reused over 50,000 square meters of equipment —

from its facilities in Castle Bromwich, which ceased production last year, and

Graz, Austria; and its Electric Propulsion Manufacturing Centre

(EPMC) in Wolverhampton — and redeployed it across JLR sites in the

UK and Nitra, Slovakia. Meanwhile, hundreds of secondlife robots are now

installed at Solihull, Halewood and the Wolverhampton EPMC to produce

JLR’s next-generation electric vehicles and battery packs.

In addition, 18,600 tonnes of scrapped metal from Castle Bromwich and Graz have

been sent to a supplier for recycling — helping to enable the reduction of CO2e

emissions by 1,258kg per tonne of new steel generated from scrapped metal.1

“As we are entering a critical phase in our electrification journey, JLR aims to

act as a responsible user of resources by enhancing product utility and

longevity, and maximizing recycling and repurposing,” says Chief Sustainability

Officer Andrea Debbane. “It’s not

only the right thing to do, but it also improves profitability and increases

supply chain resilience. Through these initiatives, JLR advocates that

sustainable choices are not always more expensive — they can help reduce costs

and even become opportunities for the growth and development of our colleagues.”

JLR’s circularity drive has been led by a broad, crossfunctional group with

members from Industrial Operations through to Vehicle Programs working across

sites and technologies to identify asset reuse opportunities.

A new digital management system has also been developed inhouse, aiming to

manage the life of every vehicle program asset from acquisition through to sale,

scrapping and reuse. The solution will include an internal marketplace where a

catalogue of assets will be available for purchase, streamlining and scaling up

future projects. Across facilities, the teams have also built new technical,

maintenance and safety skills — bringing refurbishment and recalibration of

tools to production standards on site.

Circularity plays a major role in JLR’s transformation in becoming a more

sustainable, modern luxury business. Other circularity efforts include a

partnership with energy

giant Pramac

to develop a portable, zero-emission energy storage unit powered by second-life

batteries from the all-electric Jaguar

I-PACE.

1Supplier data: 442kg CO2e per tonne of new steel created from scrapped metal

vs 1,700kg CO2e per tonne of new steel created from scratch (as of 29th April

2025).

Get the latest insights, trends, and innovations to help position yourself at the forefront of sustainable business leadership—delivered straight to your inbox.

Sustainable Brands Staff

Published Jul 8, 2025 8am EDT / 5am PDT / 1pm BST / 2pm CEST