Earlier this month, dairy giant Danone

announced it

had cut methane emissions from its global fresh milk supply chain by over 20

percent since 2020. That’s a big deal, given that methane is more than 80 times

more potent than carbon

dioxide

over a 20-year period.

The company — which sources milk from over 50,000 farms across 20 countries —

claims to have achieved this through a combination of feed additives, improved

manure management and more regenerative grazing

practices.

It’s the kind of

progress

we need much more of. Agriculture is responsible for about a third of global

greenhouse gas emissions; and although CO2 dominates the headlines, it’s

methane and nitrous

oxide

from farming that are doing outsized damage.

But done right, agriculture can capture carbon, restore ecosystems and feed a

growing global

population

without wrecking the planet. If we can equip farmers with the right tools and

incentives, the sector has the potential to shift from climate problem to

climate powerhouse. Fortunately, innovation is helping to turn the tide. Across

the globe, a new wave of agri-tech startups, equipment makers and science-led

initiatives are helping farmers reduce emissions without sacrificing yields,

income or food security.

In our second edition of Innovation

Watch, we

spotlight five breakthroughs making sustainable farming more viable and more

profitable — from zero-emission tractors to fertilizer made from air.

Smarter tractors: Zero-emission farm vehicles that save money and lungs

Image credit: Moonrider

Image credit: Moonrider

Indian startup Moonrider has developed a

zero-emission, heavy-duty, all-electric tractor built to replace diesel

machines on farms, without the higher price tag.

How does it work?

The battery-powered tractor features a patent-pending, oil-cooled thermal

system; runs for seven hours on a full charge; and supports rapid recharging in

under 30 minutes. It also comes with remote diagnostics, an intuitive app and

fleet support tools — all designed to keep uptime high and costs low.

Why should climate-conscious companies care?

Because diesel tractors don’t just emit CO₂, they also release toxic

particulates that harm local air quality. With operational savings of up to 75

percent, this is a tech leap that makes sense financially and environmentally.

For brands supporting regenerative

ag or

decarbonising their value chains, zero-emission farm equipment could soon become

table stakes.

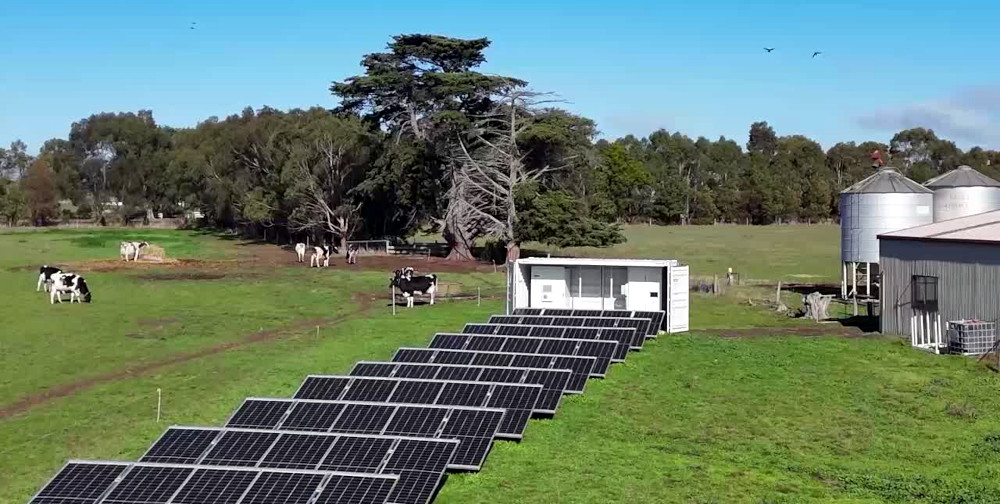

Mobile micro-grids: Clean-energy kits that power rural farms off-grid

Image credit: PHNXX

Image credit: PHNXX

Australian company PHNXX has created a modular

micro-grid system (MMS) that gives farms a fast, flexible way to adopt

renewable energy.

How does it work?

The MMS integrates solar, wind and battery storage in a containerized unit that

can be deployed in days. It can run independently or alongside national grids

and uses real-time IoT to optimise usage. Unlike traditional systems, it’s built

to move and scale as needed.

Why should climate-conscious companies care?

Because it eliminates the twin barriers of high upfront costs and complex

installs. For farms in remote or unstable energy zones, it means more

reliability and less diesel use. And for companies depending on low-carbon

agri-sourcing, it’s a practical and proven way to cut emissions at the farm

level.

Circular fertilizer: Turning organic waste into carbon-negative soil nutrient

Image credit:

Jenyasmyk

Image credit:

Jenyasmyk

UK startup Kairos Carbon has developed a

closed-loop system that turns agricultural and food waste into fertilizer,

clean water and carbon-negative energy — all without any added energy input.

How does it work?

The process uses hydrothermal conversion to break down organic material. It

extracts essential nutrients including nitrogen and phosphorus, sequesters

carbon underground, destroys pollutants including

PFAS,

and generates both electricity and purified water.

Why should climate-conscious companies care?

Because fertilizer production is a hidden climate driver, and this tackles the

problem at both ends — eliminating waste and scarcity — transforming would-be

environmental liabilities into usable resources. For companies looking at

regenerative agriculture or nature-based solutions, this is what circular

farming tech actually looks like. And with trials already underway, it won’t

stay niche for long.

Precision spraying: ‘Sticky’ droplets that cut chemical use, water pollution

Image credit: AgZen

Image credit: AgZen

A spray coating technology developed at MIT helps pesticides, herbicides

and fertilizers stick to plant leaves rather than bouncing off — cutting

chemical use, runoff and costs.

How does it work?

The system coats each droplet with a microscopic layer of oil, dramatically

improving its adhesion to the leaf surface. In tests, this increased

‘stickiness’ by up to 100 times. Farmers don’t need to overhaul their equipment

— just swap in a new nozzle. Familiar ag additives such as surfactants can mimic

the same effect.

Why should climate-conscious companies care?

Because inefficient spraying wastes money and pollutes waterways. The startup

behind the tech, AgZen, claims its RealCoverage

platform helps cut pesticide use by up to

50 percent. And with food production under pressure, better precision means

higher yields with lower impact. It’s a win for farmers, ecosystems, and brands

chasing cleaner ag footprints.

Air-to-ammonia: Clean fertilizer made from wind and air; no fossil fuels required

Image credit:

Aksakalko

Image credit:

Aksakalko

Researchers from Stanford University and King Fahd

University of Petroleum and Minerals have developed

a zero-emissions way to make

ammonia

— the building block of synthetic fertilizers — without relying on fossil fuels.

How does it work?

Instead of using natural gas and high-pressure reactors, the device pulls water

vapor and nitrogen from the air. Wind energy drives the air through a

catalyst-coated mesh that facilitates ammonia synthesis at room temperature and

pressure — no heat, no emissions, no heavy infrastructure.

Why should climate-conscious companies care?

Because traditional ammonia production emits 450 million tonnes of CO₂ a

year

— more than the UK. This method could allow farmers to generate carbon-free

fertilizer locally, on demand. It’s not on the market yet, but field-ready

versions could transform off-grid and smallholder farming, and slash the

footprint of food production.

Get the latest insights, trends, and innovations to help position yourself at the forefront of sustainable business leadership—delivered straight to your inbox.

Tom is founder of storytelling strategy firm Narrative Matters — which helps organizations develop content that truly engages audiences around issues of global social, environmental and economic importance. He also provides strategic editorial insight and support to help organisations – from large corporates, to NGOs – build content strategies that focus on editorial that is accessible, shareable, intelligent and conversation-driving.

Published Jun 10, 2025 8am EDT / 5am PDT / 1pm BST / 2pm CEST