Walkers, British Crisp Co unveil recyclable paper chip bags

Image credit: British Crisp Co

Image credit: British Crisp Co

This week, UK chip brand Walkers (known as

Lay’s in the US, Canada and Australia) announced the rollout of

paper outer bags for all

multipacks

of its Snack a Jacks rice cakes — a step toward its goal of decreasing the

brand’s use of virgin plastic by 65 tonnes annually.

Building on the shift to recyclable paper packaging of brands such as Nestlé’s

Yes!,

Walkers’ new paper bags are designed for easy recycling at home and curbside

collections; and the company says the transition to paper bags is expected to

cut greenhouse gas (GHG) emissions per pack by 52 percent. Following the success

of paper outer packaging across Walkers Baked

multipacks,

Snack a Jacks is Walkers’ second brand to adopt the new format.

“Easily recycled with your usual household paper recycling, these new outer

packs can be disposed of thoughtfully with little fuss,” said Snack a Jacks’

marketing manager Hannah

Freeman. “We hope our

devoted fans of Snack A Jacks will enjoy this small but important change we’ve

made to make their snacking experience even more enjoyable at home.”

Walkers parent company, PepsiCo Europe, plans to eliminate fossil-based

plastic

in its chip and snack bags by 2030 by shifting to 100 percent recycled or

renewable materials, as part of PepsiCo

Positive (pep+)

— the snack giant’s health and sustainability transformation plan — toward its

overarching goal of achieving net-zero emissions by 2040.

“Our outer paper multi-bag packs are working well on Walkers Baked, giving us

the confidence to roll out this format across more of our snack brands,” said

PepsiCo’s UK packaging sustainability lead Gareth

Callan. “The new packaging

will help further reduce our non-fossil plastic use, while also helping to lower

our carbon footprint as we work towards our commitment to creating a world where

packaging never becomes waste.”

On a similar note, artisanal snackmaker British Crisp

Co has introduced its own fully recyclable paper

chip

bag

— developed in collaboration with paper-based packaging manufacturer

EvoPak and Aquapak

Polymers.

The new packaging, developed over three years, is a unique combination of paper,

aluminum and Hydropol™ – Aquapak’s

water-soluble, biodegradable, non-toxic and marine-safe creation that it says

has all the benefits of plastic, and enables recycling and multiple end-of-life

options.

The companies say the very thin layer of vacuum-deposited aluminum keeps the

crisps fresh but doesn’t impact the recyclability of the packets.

“Today’s launch marks a significant milestone for Aquapak and our Hydropol

technology, which can be commercialized at scale,” says Aquapak CEO Mark

Lapping. “Producers now have a

viable, environmentally safe and recyclable alternative that enables full fiber

recovery in standard paper recycling and does not form microplastics in the

process.”

With its hyper-local, sustainable ethos, British Crisp Co — which both grows its

potatoes and produces its crisps in Essex, on a farm powered by renewable

energy; and can be found in British pubs, hotels, restaurants or cafes (but not

supermarkets) — offers an antidote to mass-produced snacks. Its new paper snack

bags — which will roll out for next month on the company’s Sea Salt, Salt

& Vinegar and Cheese & Onion flavor crisps – will feature the Recycle logo

and the message, “I’m Paper, Recycle Me.”

"Brits consume over eight billion packets of crisps each year, the majority of

which are not recyclable and end up in landfills or incinerators – that's a lot

of waste and a huge environmental problem," said co-founder and CEO Tom

Lock.

"In partnership with Evopak and using exciting new polymer technology, we have

created the first fully recyclable crisp packet – something that consumers have

been demanding for a long time.”

Daniel

McAlister,

director of business operations at Evopak,

said

the packaging “costs the same as existing materials” and could be used in a

range of applications from snacks to pet products.

Mars powers packaging progress with digital simulations

Image credit: Ansys

Image credit: Ansys

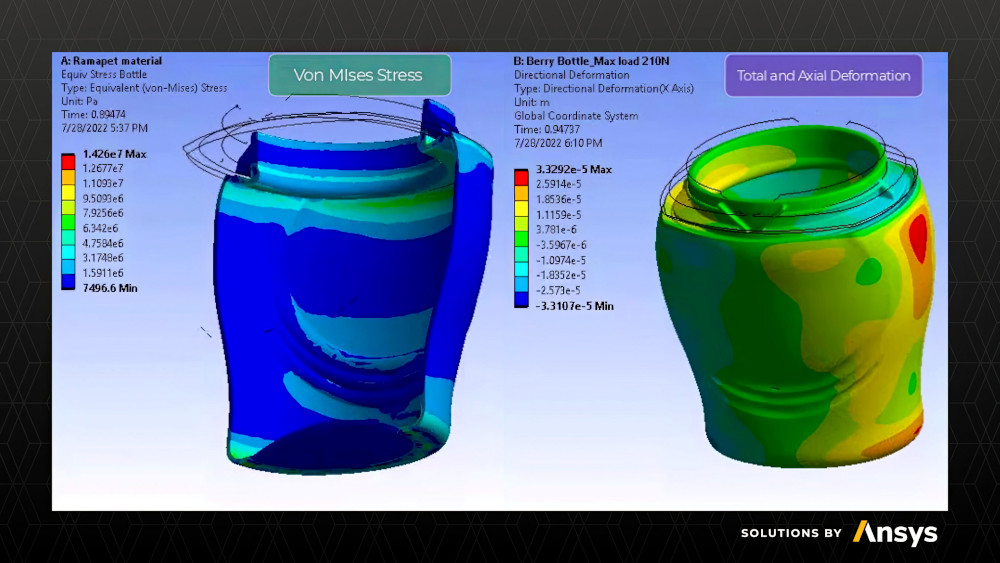

Meanwhile, Mars recently announced a collaboration with

engineering software giant Ansys in which the

multinational CPG company adopts simulation software primed to reimagine its

packaging-innovation process.

The maker of household-name brands including M&M's, Snickers and Royal

Canin is set to leverage Ansys’ digital-simulation approach to perform virtual

testing and prototyping on new packaging innovation, initially across its

snacking portfolio.

Ansys’ multi-physics simulation technology minimizes the need for extensive

physical testing during the packaging-development process and provides in-depth

insights into various aspects of the complex production phases — including

wrapping, drop tests and failure scenarios.

The partnership with Ansys illustrates Mars’ commitment and investments to

supercharge efforts to achieve its aim of using 100 percent reusable, recyclable

or compostable packaging for its products.

By implementing simulation software, Mars aims to facilitate a more nimble,

digital-first development environment — spanning from design to manufacturing —

making the process easier and more efficient for its team of R&D experts as the

company looks to expedite the pace of progress across its packaging ecosystem.

"We continue to see the impact and potential of simulation and digital

engineering in progressing sustainability initiatives throughout the world,"

said Walt Hearn, SVP of worldwide

sales and customer excellence at Ansys. " Mars' more sustainable approach to

development sets a terrific example for other manufacturers to adopt new

solutions that move us all toward a cleaner planet."

Researchers at Mars have already reported reductions in development time of up

to 40 percent through computer modeling and in the quantity of plastic purchased

by Mars for testing by approximately 246 tons. The food and pet care provider

has said that it is working to redesign more than 12,000 packaging types across

its portfolio to fit with the recycling infrastructure that either exists today

or is likely to exist in the future, making it easier for consumers to recycle

their packaging.

"In the world we want tomorrow, no packaging becomes waste," said Qing

Qi, VP of R&D global innovation

at Mars Snacking. "This vision is at the heart of our multibillion-dollar

Sustainable in a Generation

plan

and will only become a reality by taking unconstrained strides — leveraging

breakthrough science, innovative thinking and partnerships to push the

boundaries of what's possible.”

Get the latest insights, trends, and innovations to help position yourself at the forefront of sustainable business leadership—delivered straight to your inbox.

Sustainable Brands Staff

Published Apr 5, 2024 8am EDT / 5am PDT / 1pm BST / 2pm CEST