A major collaboration between Procter & Gamble (P&G)

and Durham University and Newcastle

University in the UK has yielded a new framework

that supports industrial decarbonization of chemicals in the consumer goods

sector, through the use of captured carbon as a feedstock.

The research asserts that using carbon

capture

to valorize industrial flue gases — the byproducts of burning fuel in

industrial processes such as power generation and manufacturing — into products

is a win-win for lowering costs, diverting climate-changing emissions and decarbonizing consumer products.

Lower-impact, circular chemical production

The P&G-Durham-Newcastle partnership builds on the work of the Flue2Chem

project

— a two-year program in which P&G, BASF, Unilever and 12 other

organizations worked to develop a new value chain to convert industrial waste

gases into sustainable feedstocks for consumer products.

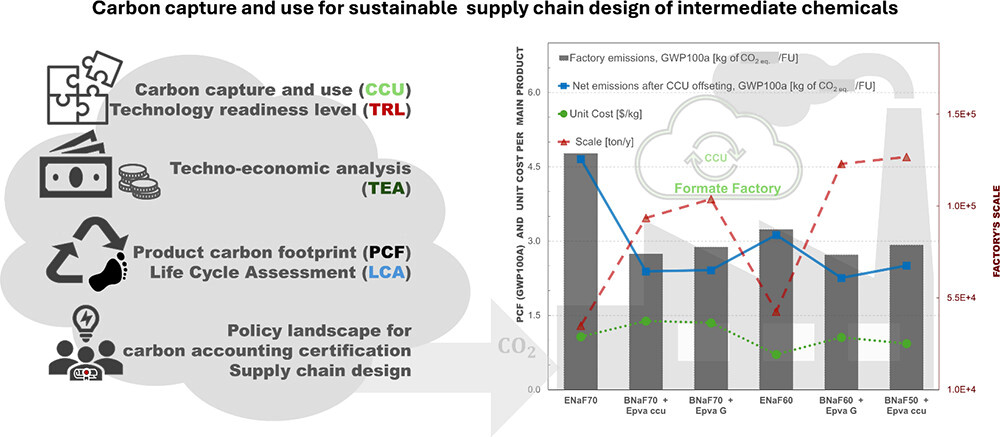

This latest, 18-month partnership has produced a robust tool that enables

chemical manufacturers to assess and compare existing and emerging technologies

based on environmental impact, economic viability and alignment with policy. The

framework integrates lifecycle

assessment

(LCA), technoeconomic analysis (TEA) and regulatory

considerations

to help businesses make informed decisions about low-carbon manufacturing

routes.

Image credit: ACS Sustainable Resource

Management

Image credit: ACS Sustainable Resource

Management

“This framework empowers stakeholders to evaluate low-carbon options and make

strategic decisions about which technologies to scale,” said Professor Nalan

Gulpinar from Durham

University Business School, who led the research team. “The collaboration also

supports the development of sustainable products for the global market.”

Industrial decarbonization requires a holistic approach that includes supply

chain design, TEA and LCA to drive the transition toward a low-carbon future.

CO2 emissions can be upcycled

into chemical feedstocks for everything from

apparel,

auto

parts,

carbonated

beverages

and detergent (P&G has already explored the use of captured carbon in its

Tide

brand) to

footwear,

fuel,

personal-care

products,

plastics

and more. The study asserts that scaling sustainable supply management by upcycling CO2

into chemical feedstocks across industries can be particularly impactful: For example, turning flue gases from

steelmaking into feedstock could mitigate up to 2.4 percent of greenhouse gas

emissions in the UK alone. The research also underscores the importance of

integrating low-cost, clean sources of

electricity

and

hydrogen

into manufacturing systems to maintain profitability.

“Making sustainable chemicals profitable will be key to growing manufacturing

while achieving industrial decarbonization,” said Newcastle University Professor

Elizabeth

Gibson. “This

work shows how that ambition can be realized.”

An impactful collaboration model

The project was delivered through a Knowledge Transfer

Partnership

(KTP) — a UK-wide scheme in which businesses form strategic partnerships

with academic institutions to develop new products or services, expand markets,

and improve efficiency or organizational performance to address core strategic

challenges — co-funded by UK Research & Innovation

through Innovate UK and P&G. The ongoing success of

KTPs reflects the potential of academia

and industry working together to solve complex global challenges.

P&G and Durham first began collaborating in

2023,

when Durham researchers teamed up with the consumer goods giant to bring new

synthetic capabilities to P&G’s Newcastle Innovation Center.

"Improving supply chain knowledge is increasingly critical in today’s world, and

having a sound methodology in support of more sustainable sourcing is key,” said

Ian

Blakemore,

Knowledge Transfer Adviser at Innovate UK Business Connect. "This unusual

project delivered this in a relatively short time — demonstrating that KTPs are

an excellent way of delivering improved understanding, supporting change in

complex systems."

The future of sustainable manufacturing

This partnership demonstrates how academic expertise, when combined with

industry insight, can shape the future of sustainable manufacturing.

Initial findings of the carbon-captured chemicals study are now published in

ACS Sustainable Resource

Management, with

further publications planned. The team says the research is already influencing

innovation across the chemical manufacturing sector.

Get the latest insights, trends, and innovations to help position yourself at the forefront of sustainable business leadership—delivered straight to your inbox.

Sustainable Brands Staff

Published Jun 13, 2025 8am EDT / 5am PDT / 1pm BST / 2pm CEST