Europe in the 19th century, the US in the 20th century, and China in

recent decades have all experienced exponential economic growth by “scaling up”

vertical manufacturing — that is, by centralizing industrial activities in large

factories. But this energy-intensive mass production model has depleted natural

resources

and seriously damaged our environment (the industrial sector accounts today for

nearly

one-third

of US greenhouse gas emissions).

Today, a massive reindustrialization is

underway

in the US and Europe as Western nations try to bring back

manufacturing

that they previously outsourced to low-cost nations such as China. Learning from

the past, US and European manufacturers should avoid scaling up vertically their

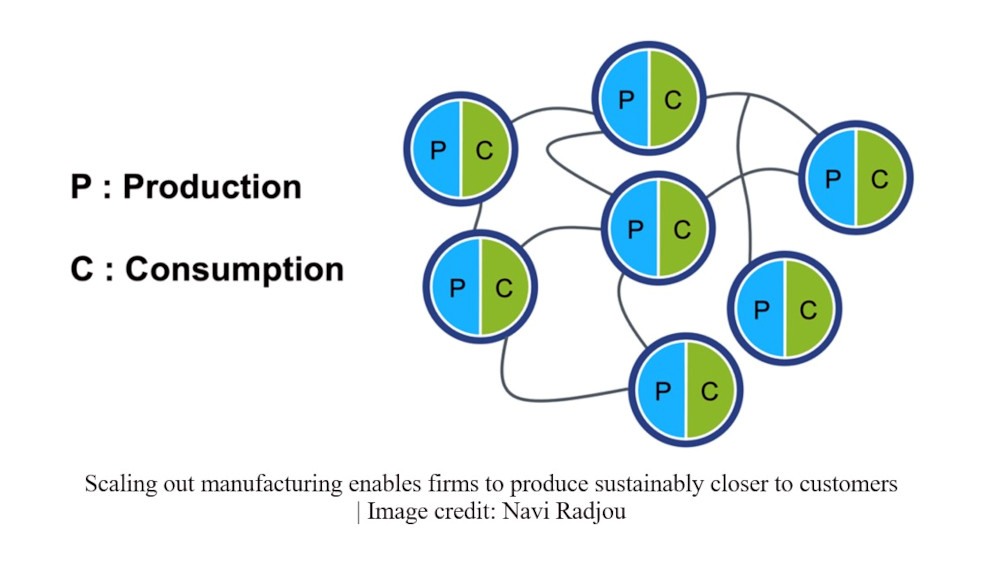

operations in gigafactories. Instead, they should “scale out” horizontally —

using a distributed supply network with many small, hyper-agile factories

located closest to customers (see Figure below).

The multiple benefits of scaling out manufacturing

By scaling out their manufacturing and producing in small factories located

closer to customers, businesses can reap many benefits:

Slash fixed costs and operating expenses

Businesses can avoid the huge capital expenditures (CapEx) needed to build and

run giant high-volume factories. For example, Tesla intends to invest $10

billion

to construct its gigafactory in Mexico — which is nearly twice more than

its Berlin

gigafactory.

In comparison, French electric mobility startup Avatar

Mobilité is building a network of micro-factories

that can be set up cost-effectively and rapidly across France and in

developing nations. Avatar is the creator of

Ulive — an ultralight

electric vehicle that weighs only 350 kg (771 pounds) and consumes three times

less energy than a traditional EV. In each Avatar micro-factory — no bigger than

a spacious garage — local entrepreneurs can assemble the Ulive in a matter of

hours. The Ulive is sold at €15,000 ($16,600), which is a bargain compared to

EVs sold in the US that cost on average

$60,544.

Shrink logistics costs

Firms can curb inbound logistics costs by sourcing raw materials and components

locally, removing the need to transport them from various distant suppliers to a

centralized factory. And by selling their finished products directly to

customers located near their micro-factory, businesses can forego intermediaries

and slash distribution expenses and emissions by avoiding shipping to distant

points of consumption.

For instance, Canadian startup Relocalize is on a

mission to decarbonize and hyper-localize food and beverage production — which

contributes 37 percent of global GHG emissions. Relocalize’s high-tech

micro-factories can produce, package and pelletize food and beverage items on

the spot at grocery distribution centers — hence, removing middle-mile logistics

and drastically reducing GHG emissions, water use and plastic pollution.

Relocalize’s first solution is an autonomous micro-factory — which can fit

inside a repurposed shipping

container

— that can produce packaged ice in certified plastic-negative

bags on-demand and on-site at retailer

distribution and fulfillment centers. This eliminates the crazy need to ship

ice over 1,500

miles

to distribution centers, as it’s done today.

Boost resilience and agility

Distributed manufacturing offers greater supply chain

redundancy

than centralized production. In case micro-factory X in location A malfunctions,

micro-factory Y in nearby location B can take over the tasks and complete

pending customer requests. Even better, you can expedite a “factory in a

box”

— a pre-assembled manufacturing facility in a container — that can be quickly

set up at location A for emergency production while micro-factory X is being

repaired.

For example, global biopharmaceutical firm Bayer piloted a flexible

manufacturing project named F3 (flexible, fast and future)

Factory — a portable,

modular production unit designed to fit within a container. This mobile factory

can quickly be deployed at the customer’s industrial location to manufacture and

distribute a variety of customized chemicals in small quantities. The F3 pilot

project demonstrated a 40 percent decrease in capital investments, 30 percent

energy savings, 30 percent reduction in CO2 footprint, and a significant

improvement in time to market.

Deliver personalized goods flexibly and profitably

During the 19th and 20th centuries, firms scaled up their production in

ever-larger factories to achieve economies of scale. They vied to lower

expenses by mass-producing standardized goods. Today, however, eco-conscious

buyers seek customized

products

that are made closer to where they

live.

Therefore, businesses need to revamp their industrial model in order to achieve

economies of

scope. They must

learn to produce cost-effectively, in low volume, a wide variety of personalized

products in digitally optimized micro-factories located in proximity to

customers. To realize economies of scale, you must

become more efficient. To achieve economies of scope, you must boost your

agility.

AI-powered industrial automation solutions can deliver this agility. San

Francisco-based startup Bright Machines

(BM) has created totally automated and easily configurable micro-factories, with

which users can produce a wide range of items — from electronics to home

appliances — near the customer, enabling flexible and eco-friendly

manufacturing. Using BM’s flexible automation solutions, customers have been

able to launch new products 28 times quicker compared to manual assembly and

boost their production throughput by 2.5 times.

Become more sustainable

By outfitting their micro-factories with digital fabrication technologies

(DFTs) such as CNC machining and 3D

printing,

companies can achieve four advantages:

-

utilize fewer raw materials

-

produce less waste

-

reduce their carbon footprint, and

-

lower transportation expenses.

Additive

manufacturing

(a fancy name for 3D printing) is “frugal,” as it generates 70-90 percent less

waste

compared to traditional manufacturing methods.

Industry

4.0

players including Xometry,

Protolabs and Sybridge operate

a distributed network of small-scale factories run by DFTs such as 3D printers

that eliminate the necessity of transporting components across the globe to be

assembled in a large, centralized factory. Instead, design data for a new

product can be electronically transferred to the micro-factory located closest

to a customer, where it can be 3D printed rapidly using materials that are

easily accessible in that area.

Maximize social impact in local communities

Businesses can build capacity and regenerate “left-behind” communities — such as

former coal-mining towns in the US hinterland — by setting up micro-factories

that would source from small suppliers situated nearby and train and employ

local talent.

For instance, textile-waste recycling company Re-Fresh

Global sets up microfactories in underdeveloped

communities

under a franchising model. Each recycling micro-factory, run by an entrepreneur,

employs people in the local community who also learn valuable skills to succeed

in a circular

economy. Re-Fresh

is a great example of “triple

regeneration”

(to be covered in Part 4 in this series) — a holistic approach to creating

economic, social and ecological value synergistically in disadvantaged places.

Case study: How AFYREN is scaling out the $30 trillion bioeconomy

The bioeconomy aims to

replace the toxic and polluting “petro-sourced” materials used in industrial

value chains with cleaner, “biobased” materials. The bioeconomy holds immense

growth potential: The European bioeconomy is already worth €2.4 trillion

euros;

while the US bioeconomy is today valued at over $1

trillion,

or 5 percent of US GDP. Estimated at $4

trillion

today, the global bioeconomy is poised to grow to $30

trillion

by 2050.

AFYREN is a French startup shaping the bioeconomy. It’s

NEOXY plant in Northeastern France is

a biorefinery that “upcycles” agricultural residues into seven valuable

biomolecules called carboxylic organic acids — used in fields including

animal and human nutrition, cosmetics and lubricants. AFYREN has optimized

NEOXY’s industrial processes, so it produces five times less CO2 and greenhouse

gas emissions compared to traditional methods of producing acids from fossil

fuels.

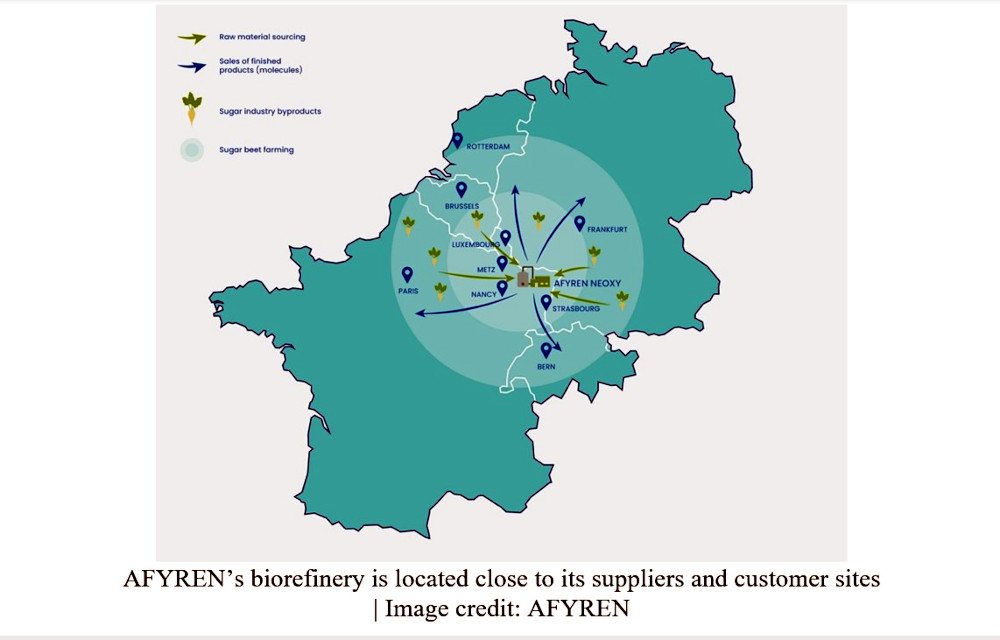

AFYREN projects a $15 billion global market for its seven biobased organic

acids. What makes its operating model most intriguing is that the majority of

its suppliers are situated within a 250 km (155 miles) radius of its NEOXY

factory (see Figure below). NEOXY supplies global customers through its

industrial facilities in Western Europe for further product processing.

In 2023, AFYREN teamed up with Mitr Phol — a

leading global sugar industry player headquartered in Bangkok, Thailand. The

plan is to establish a second biorefinery in

Thailand

to transform sugarcane byproducts from local suppliers into high-value biobased

products for Asian markets, which account for 25 percent of global carboxylic

acid demand.

AFYREN is considering the option of establishing its third biorefinery in the

United States that will transform agricultural waste — such as corn

byproducts

— sourced from US farmers into valuable products for the North American market.

Instead of scaling up its manufacturing by centralizing all its production in a

single, giant factory that would supply all global markets, AFYREN wisely

decided to “scale out” by running modestly sized factories located in two vital,

regional markets: Europe and Asia.

Every biorefinery solely utilizes raw materials abundantly available locally and

caters mostly to regional clients. AFYREN's hyper-local bioeconomy value chains

minimize carbon footprint and maximize the livelihoods of local farmers, who

earn more by selling their agricultural

waste.

By scaling out their manufacturing with a distributed network of agile

micro-factories rooted in local communities, businesses can gain in agility and

resilience and produce and deliver personalized goods faster, better, cheaper

and more sustainably.

Read more about the frugal economy:

This article has been partially adapted from the author’s upcoming book, The

Frugal Economy: A Guide to Building a Better World with

Less (2024),

published by Wiley and Thinkers50.

Get the latest insights, trends, and innovations to help position yourself at the forefront of sustainable business leadership—delivered straight to your inbox.

Navi Radjou is a French-American scholar and advisor on innovation and leadership.

Published Sep 13, 2024 8am EDT / 5am PDT / 1pm BST / 2pm CEST